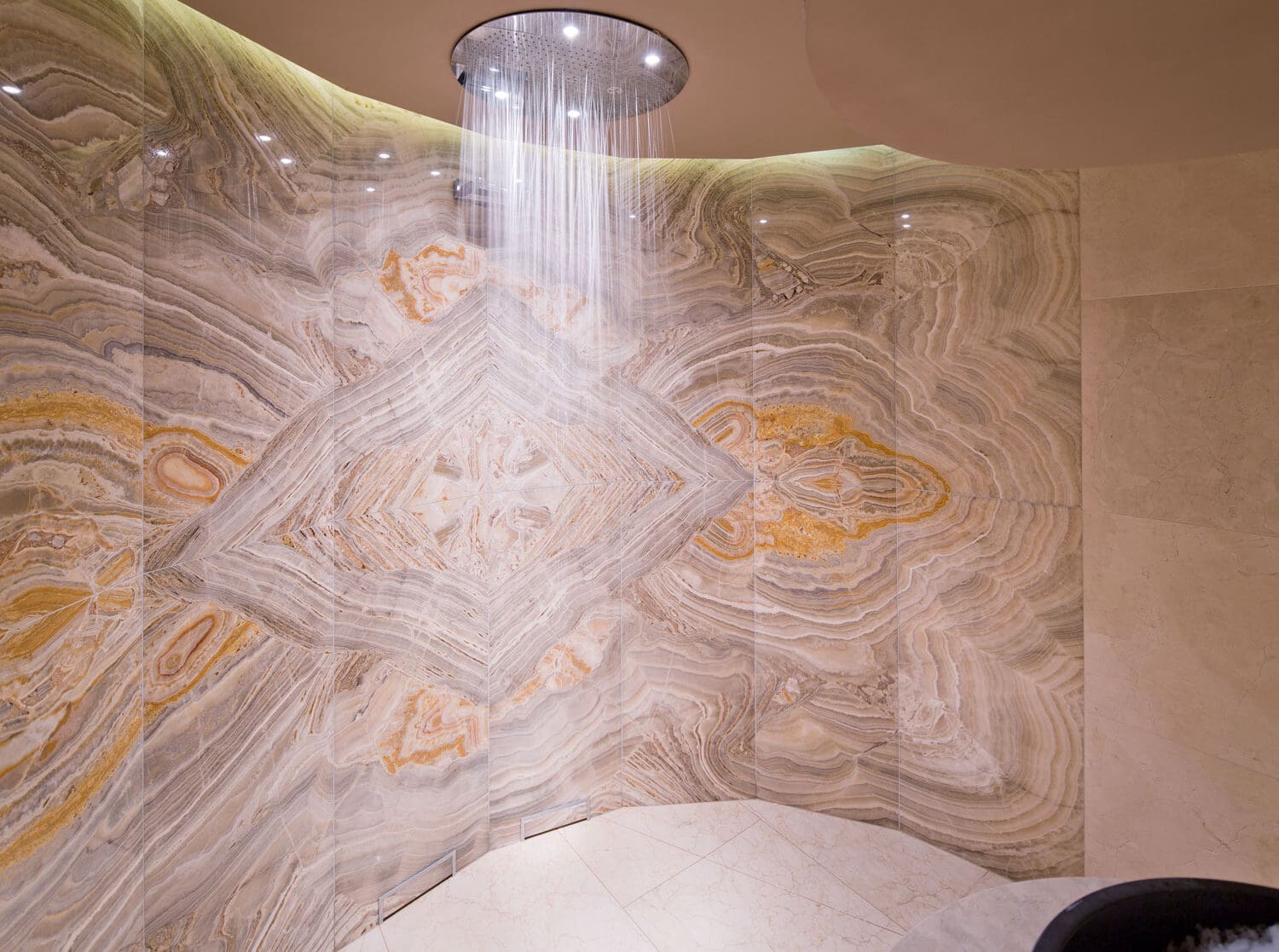

In our Made-to-Measure pillar we encompass a wide range of custom approaches that aren't necessarily driven by innovation but do require a tailored solution. This pillar includes diverse projects, from custom-designed floors with various patterns for hospitality settings to residential walls, kitchen counters, and even elevators, stairs, and bathrooms in yachts, along with art objects. We provide the unique opportunity to hand-select the perfect stone slab, custom-tailored to your specific needs. However, unlike our Bespoke service, we do not provide measuring and installation. Our commitment is to offer you an unparalleled experience, combining a personalized selection process with expert guidance.

Let us help you Contact

We source materials worldwide based on your preferences. You can choose from slab images or visit our stone atelier by appointment for a hands-on selection experience. We act as the link between the natural beauty of stone and your vision, bringing brilliance to light and making new realities possible.

Our dedicated team sources the rarest and most exclusive high quality materials according to your requirements. With over 150 quarries, our reach is unsurpassed and we are constantly in search of phenomenal unseen stones. Not only is the quality considered, but also a client’s needs in terms of colour and veining, while maintaining the highest standards of health and safety in accordance with international human rights and environmental regulations.

Our passion for stones is the key driver behind everything we do. We are equally committed to helping you create and deliver excellence in execution. Based on the design drawings provided by you, we bring your vision to life, ensuring seamless communication and coordination with a single point of contact throughout the entire process.

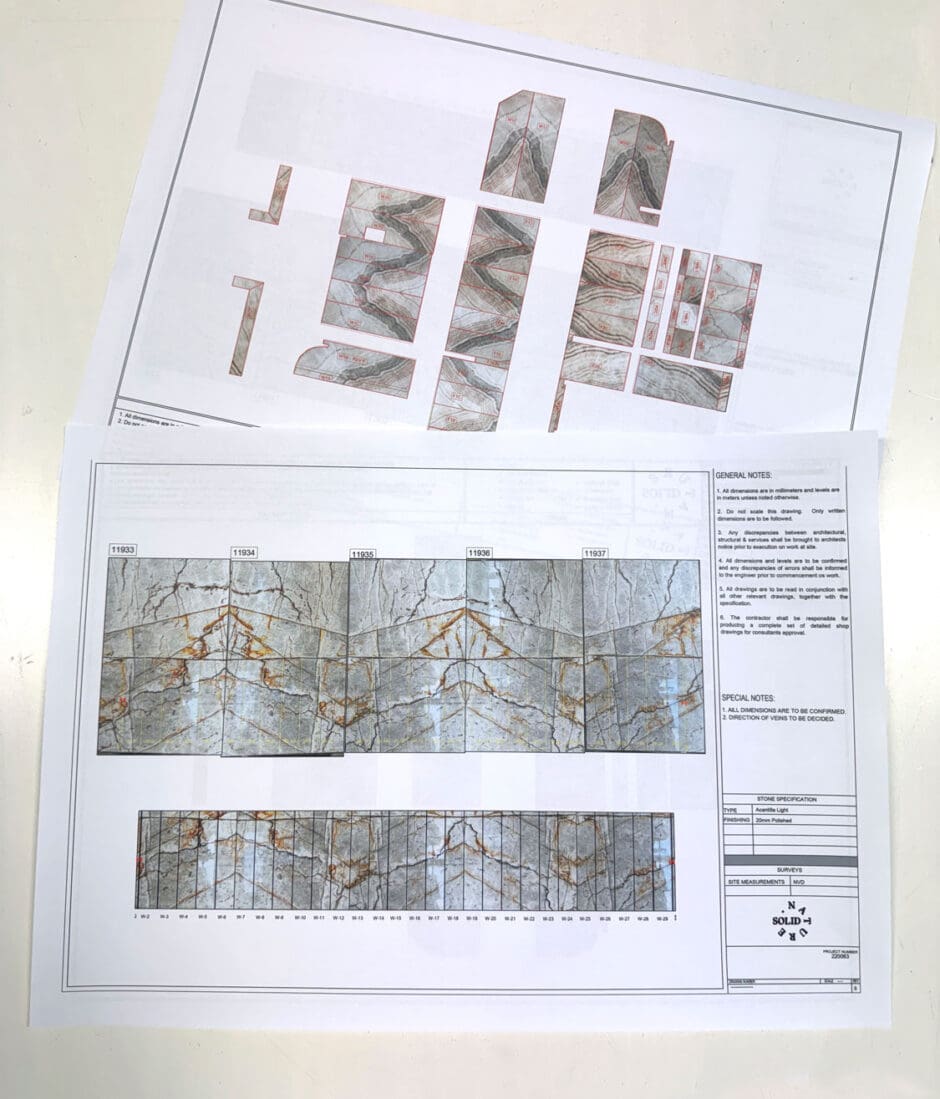

With digital dry-lay, a photograph of the specifically chosen slab is taken and digitally inserted into the project drawing for the customer’s approval before cutting begins. This ensures the stone is cut exactly as envisioned, allowing for precise customization. It also enables pre-determination of the desired bookmatch, as veins and colors in the slab can create different patterns depending on how it is cut.

Additionally, digital dry-lay is a sustainable approach that minimizes material waste. By planning cuts in advance, the risk of material misuse is significantly reduced, aligning with our commitment to responsible resource use.

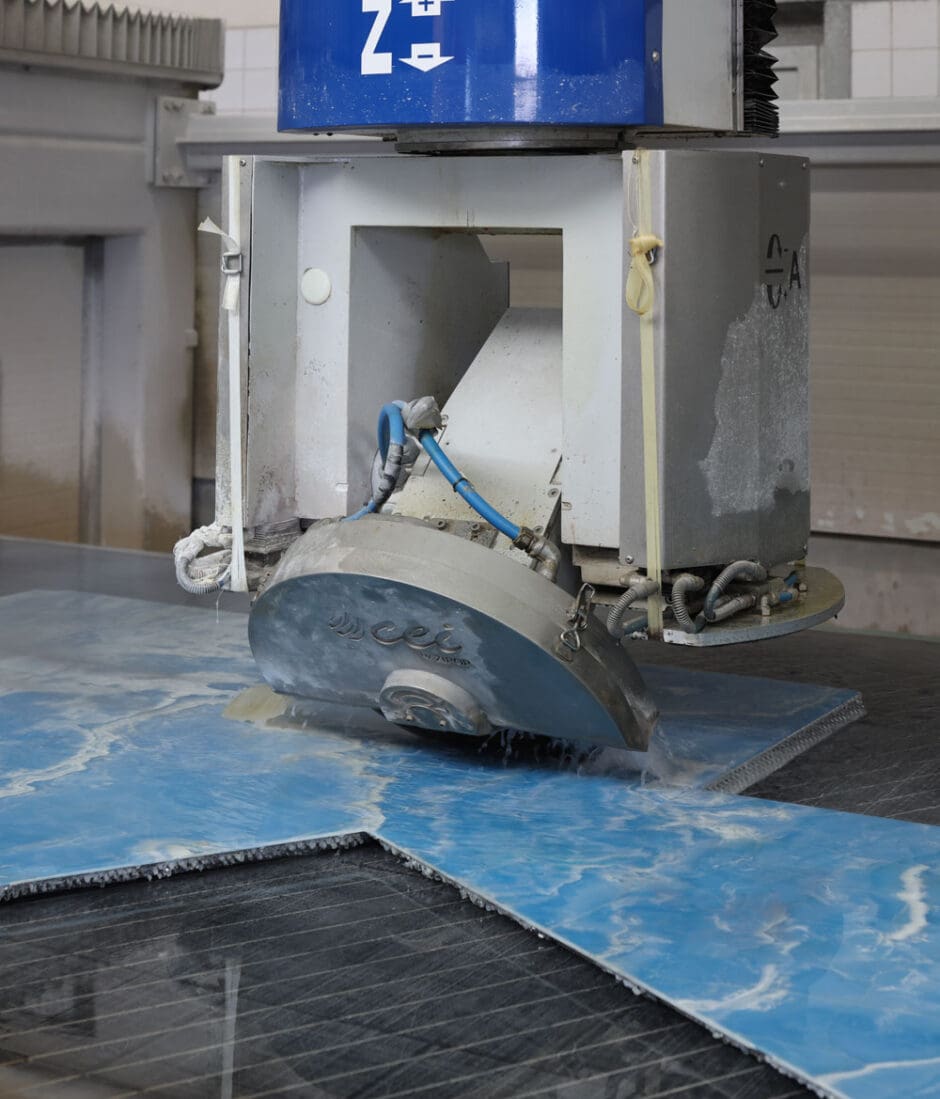

After the sourcing and digital dry-lay, we make sure our in-house production is top-notch, powered by the most advanced machinery, including CNC Waterjet and 5-axis 3D technology, ensuring precision and efficiency in every project. These cutting-edge tools, combined with expert craftsmanship, allow us to create custom designs with unparalleled accuracy and detail. Our skilled artisans bring years of expertise to the process, ensuring that each piece meets the highest standards of quality and craftsmanship, while our state-of-the-art machinery handles the technical aspects of production. This combination of technology and skill enables us to deliver exceptional results every time.

After production, we conduct a thorough final check, securely package the pieces, and prepare them for pickup.